Carbon Nanotubes (CNTs) continue to hold great promise in many areas. While our understanding of the properties of CNTs has increased, and we have made some small progress towards solving the primary production and separation issues, unfortunately, for the most part, the same obstacles that were in place 5 years ago continue to stymie research and development efforts.

Purity is definitely an issue; most producers of nanotubes now sell them based on “percent pure.” The higher the purity the higher the cost, well above $1,000 per gram in many cases.

Purity is related to “what percent is nanotubes and what is impurities” as well as “what percent is a certain type of nanotube, while the remainder is another type or types.” (Note that there are three main types of carbon nanotubes and as many as 80 sub-types, each with distinct properties). Current separation techniques simply do not produce "pure enough" batches of CNTs (at a reasonable cost).

Other major hurdles include production scaling problems (and therefore cost) and functionalization (necessary for medical uses).

Another major hurdle has been, and remains, both the public perception and the actual risk associated with these vanishingly small materials; we just don’t know, yet, all the ways in which nanotubes may prove toxic.

Expect to see nanotubes play a significant role in dozens of major industries in the near future (say 3 – 5 years) provided that the usual caveats are met: low cost and high production volumes, coupled with cost-effective separation methods.

Where strength-to-weight is an important factor, expect to see nanotubes become a significant contributing factor, first in tomorrow’s advanced aerospace and military applications, and then consumer products.

There are an increasing number of nanoscale solutions to the screening, diagnosis, monitoring and treatment of disease, many of which involve functionalized nanotubes. Expect to see nanotubes play a significant role in medicine when functionalization issues are solved (basically, when we understand more fully their properties).

Here are some of the nanotube articles that have appeared in the period spanning March 29 to April 4, 2007.

The Department of Physics, Panjab University, is working on a project that could have a far-reaching impact on defense warfare. The department is trying to exploit nanotechnology to develop a material, which when used as a coating, would increase the shock absorbing capacity of the object on which it would be coated. Prof V K Jindal, faculty member of the department and in-charge of the project, said carbon nanotubes are being used to develop the material. “We are studying the properties of carbon nanotubes. The tubes are very strong and are, hence, durable. One possibility is to make a liquid that can be used as the coating substance.”

RR: At the very least, they will learn more about the properties of nanotubes, as well as how to produce them.

From: PU research on nanotechnology could impact defense warfare

http://cities.expressindia.com/fullstory.php?newsid=229446

Polynano™ carbon nanotube field emission device (CNT-FED) features perfect flat outer screen surface, flat rear screen, very thin thickness, high beam current output of carbon Nanotube emission cathode, circle phosphor dot screen anode, monochrome output, see-through type, wide-environmental operation application. Monochrome display for 32x32 resolution character and image interface application. Its use is very effective for established high visibility wording and character recognition icons.

RR: This bit is a feature on Polytron Technologies, Inc. Their CNT-FED is one of many CNT-based screen technologies. The company that brings an inexpensive and easy to mass produce screen to market will be in an enviable position.

From: Polytron Technologies, Inc.

http://www.glassonweb.com/articles/article/407/

NEC Corp has announced it prototyped a field effect transistor (FET) coating using carbon nanotube solution and achieved an on/off source-drain current (comparison of current when the power is on and off) of up to 107 by making channel length longer. Given low temperature during manufacturing process, the carbon nanotube FET coating is expected for application to flexible devices using plastic substrates.

RR: As I say above, the company that brings an inexpensive and easy to mass produce screen to market will be in an enviable position.

From: NEC Prototypes Carbon Nanotube Transistor Coating

http://techon.nikkeibp.co.jp/english/NEWS_EN/20070403/130098/

A team of University of Pennsylvania and Rice University researchers have added a significant new step to the creation of materials fortified by single-walled carbon nanotubes, or SWNTs, resulting in a nylon polymer composite with greater strength and toughness and opening the door for researchers to broadly improve the mechanical properties of such composites at the molecular level. The resulting nanocomposites with the covalent bond exhibit as much as 160 percent higher modulus, 160 percent higher strength and 140 percent higher toughness.

RR: Yet another example of where our understanding of the nanoscale will likely yield products with vastly improved characteristics. As they say “Nanotube-based composites have the potential to revolutionize fabrics, structural materials for aerospace, electrical and thermal conductors for energy applications, nano-biotechnology and other disciplines.” Perhaps an understatement given the amount of R&D investment in this area, and the well-established potential of nanotubes.

From: Seeking the Next Kevlar: Penn Researchers Fine Tune Nanotube/Nylon Composite Using Carbon Spacers

http://www.nanotech-now.com/news.cgi?story_id=21684

Researchers from the three University of Texas campuses in the Dallas-Fort Worth metropolitan area are combining their expertise in biomedical science, engineering and physical sciences on projects aimed at solving real-world medical problems. Teams receive up to $100,000 for their respective projects, which program leaders say will allow the researchers to attract additional external funding from conventional sources, such as federal agencies.

Among the funded projects:

“Fabrication and evaluation of a combined near infrared fluorescence and hyperspectral imaging system for carbon nanotube vectors" - Dr. Harold "Skip" Garner, professor of internal medicine and biochemistry at UT Southwestern, and Dr. Paul Pantano, associate professor of chemistry at UT Dallas. This project relates to the use of carbon nanotubes as sensors within living cells as well as their potential use in targeted cancer therapies.

RR: You’ll be reading a lot more about nanotube/sensor applications in the future as we learn how to functionalize the CNTs. This area holds great promise in the screening, diagnosis, monitoring and treatment of disease.

From: UT Metroplex institutions to collaborate on biomedical research

http://www.nanotech-now.com/news.cgi?story_id=21687

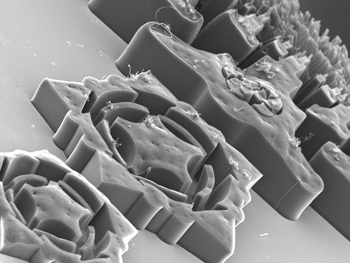

Despite the attractive electrical properties and physical features of single-walled carbon nanotubes, incorporating them into scalable integrated circuits has proven to be a challenge because of difficulties in manipulating and positioning these molecular scale objects and in achieving sufficient current outputs. Now, researchers at the University of Illinois, Lehigh University and Purdue University have developed an approach that uses dense arrays of aligned and linear nanotubes as a thin-film semiconductor material suitable for integration into electronic devices.

RR: This is one of many R&D efforts aimed specifically at incorporating nanotubes into electronics. Many in the know figure that nanotubes are one way that we may extend Moore’s Law past 2012-2015.

From: Linear arrays of nanotubes offer path to high-performance electronics

http://www.nanotech-now.com/news.cgi?story_id=21429

Raymor Nanotech will begin to offer in the second quarter of 2007 various high purity grades of single-walled carbon nanotubes (C-SWNT) for emerging markets. To achieve this, Raymor Nanotech launched its Purification department in 2006.

RR: Another step towards creating purified CNTs. They do not, however, state the cost, nor the volumes expected. And note that the most pure type is still not 100% pure (“the Purified Grade is a high quality SWNT product with excellent graphitization, an average length of 5 microns, and a very low metal (less than 1.1 atomic %) and amorphous carbon content”).

From: Raymor will Offer Various High Purity Grades of Single-Walled Carbon Nanotubes for Emerging Markets in the Second Quarter of 2007

http://www.nanotech-now.com/news.cgi?story_id=21558

New research published in the March 19 issue of Applied Physics Letters suggests that carbon nanotubes may soon be integrated into ever-shrinking cell phones, digital audio players, and personal digital assistants to help ensure the equipment does not overheat, malfunction, or fail.

RR: Another example of the vast potential of nanotubes. “Carbon nanotubes, however, maintain their impressive combination of high strength, low weight, and excellent conductivity, and the carbon nanotube coolers can be manufactured very cost effectively, Vajtai said.”

From: Cool Findings: Nanotubes Could Improve Thermal Management in Electronics

http://www.nanotech-now.com/news.cgi?story_id=21559

Please contact me at rocky at access-nanotechnology.com for detailed reports on this or any other "nanotech" area, including advanced materials, nanomedicine, energy, etc.